Lisa

Marketing department

Tel:+86-755-27252129

Fax:+86-755-27864271

ADD: B3 BUILDING, LANTIAN TECHNOLOGY PARK, SHAJING TOWN, SHENZHEN CITY, CHINA.

Selective laser sintering insert greatly reduces lead-time of mold manufacturer

Selective laser sintering insert greatly reduces lead-time of mold manufacturing

Metal powder composite forming method is an integration of Selective Laser Sintering (SLS) and common CNC machining, it is the combination of Lamination modeling and opposite reductive manufacturing, this method unite advanced material, software, laser and CNC technology. The part accuracy can reach up to ±0.005mm, and the hardness after heat treatment can reach up to Hrc54, satisfying the dimension and hardness request of a precision plastic injection mold. Consequently the customer and tool maker got a very valuable solution for manufacturing of mold component.

For the past few years, the effort of bringing rapid prototyping technology into injection mold industry has never stopped. Especially in Europe, Selective Laser Sintering (SLS) and Selective Laser Melting (SLM) have been successfully used to directly make a metal part. And now the development has reached the level of directly making components for plastic injection mold as experiment.

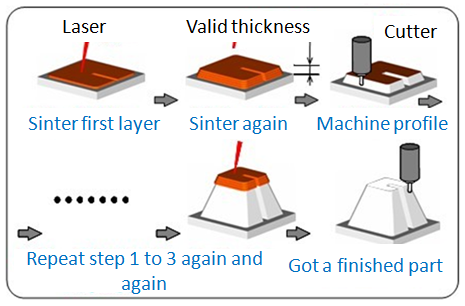

Metal powder composite forming method process

The manufacturing process is:

①The laser sinter the metal powder on first layer

②Cover the second layer powder and sinter again and again until the material is thick enough for the cutter

③The CNC cutter machines the material

④Repeat step 1 to 3 again and again

⑤Finally got a finished part

Example study: Automotive auxiliary fuel tank mold got a 60% cycle time reduction

The part in below picture is a auxiliary automotive fuel tank jet pump and overflow component, the JP insert is made by metal powder composite forming method that creates a profiled cooling into a thin cavity insert, which can not be done by a traditional machining method. Comparing to solid insert, the molding cycle time has been greatly reduced from 25s to 10s.